Bonding metal instead of welding – Welding is silver, bonding is gold

Welding metal has long been regarded as the king of joining techniques. Two materials are joined by local heating and fusion. This process is well established across industries and is the method of choice wherever durable and strong joints are required. Under the right conditions, welding is still the number one solution. But such conditions are not always present. Especially with heat-sensitive materials or precision components, thermal methods such as conventional welding or brazing/soldering by induction heating are not always ideal.

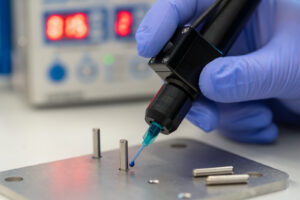

An alternative once underestimated is now gaining importance: with the right dispensing and mixing technologies, modern adhesives can create joints just as strong – even with demanding materials like metal. In this Magazin-article, we explain what to consider when you decide to bond metals instead of welding them.

The key question: can you (really) bond metal?

Most people think of welds, rivets or screws for durable metal joints. Adhesive bonds are seen as weaker and suitable only for a few cases – but that is a misconception. Combined with suitable dispensing equipment and innovative engineering solutions, modern adhesives are highly effective for bonding metals to other materials, even under challenging conditions.

Today, adhesive systems exist that can withstand high mechanical loads, absorb temperature fluctuations and adhere reliably to a wide range of substrates. Bonding metal to glass, wood, granite or concrete is no problem anymore. “Bond instead of weld” is the guiding principle.

The benefit: no heat input. That protects sensitive materials and avoids stresses or warping inside components. For metal-to-metal or metal-to-other-material bonds, adhesive, consumables and processing technology must be carefully matched. Proper substrate preparation and precise adhesive dosing with high-quality systems (dispensers, needles, dosing units, etc.) are essential.

Bonding metal to wood

Joining metal and wood places high demands on the adhesive and process. While metal stays dimensionally stable, wood expands, contracts and changes with temperature or humidity.

Adhesives used must be flexible, maintaining bond strength while compensating for movement. Reactive polyurethane or epoxy systems are commonly applied. They adhere to both metallic and porous substrates. Wood must be dry, clean and mechanically sound. On coated surfaces, light sanding improves adhesion. Plasma activation can be used for advanced applications to optimise surface energy.

Bonding metal to glass

Glass is smooth, non-porous and brittle, requiring special care. Since thermal joining is not feasible, bonding has become the standard in many industries (lighting, architecture, display construction).

Transparent adhesives with strong initial tack, such as silicone, acrylate or UV-curing systems, are preferred. Surfaces must be grease-free, dry and dust-free. Primers may improve long-term durability. Careful dosing avoids bubbles or excess adhesive.

Bonding metal to granite or concrete

Mineral substrates such as granite, concrete or natural stone limit the use of mechanical joints: drilling weakens the material, welding is impossible. Bonding offers a reliable alternative.

Since these substrates are porous and can absorb moisture, surfaces must be clean, dry and solid. Primers may be used for irregular or highly absorbent surfaces. Thixotropic, paste-like adhesives with strong initial tack are applied – such as 2K epoxies or single-component MS polymer systems. Outdoor applications require weather and temperature resistance.

Bonding metal to metal

Metal-to-metal bonds, especially outdoors, must withstand thermal fluctuations, humidity, UV and mechanical stress. High-performance adhesives are essential. Two-component epoxies or polyurethanes are proven solutions. Metal surfaces must be degreased and possibly roughened (sanding, blasting). Primers or plasma activation can enhance adhesion. Precise dosing ensures long-term durability.

Step by step: bonding metal instead of welding

- Choosing the right adhesive – Depending on materials, environment and load. 2K epoxies are typical; PU or MS polymers for flexibility.

- Surface preparation – Surfaces must be clean and suitable, with proper roughness where required.

- Applying the adhesive – Even, well-mixed application in the correct amount, preferably with volumetric dispensers.

- Curing and finishing – Adhesives must cure undisturbed before load or further processing. Residues can be removed mechanically or with suitable cleaners.

Firmly bonded – Innovative adhesive technology instead of “weld outbursts”

Successful metal bonding requires adhesive, materials and dispensing technology to be perfectly coordinated. As specialists in joining technology, robotics and contract manufacturing, we design processes holistically. From component selection to laboratory trials and integration into production, H. Sigrist & Partner AG supports you with technical expertise and practical solutions.

FAQ: Bonding metal instead of welding

Can metal really be bonded permanently instead of welded?

Yes, with the right adhesive and precise processing, bonds can be strong and durable.

Which materials can be bonded with metal?

Metal-to-metal, as well as combinations with glass, wood, concrete or stone.

When is bonding more suitable than welding?

For heat-sensitive materials, complex geometries, or series production requiring reproducibility.